- Home Page

- Company Profile

-

Our Products

- Microscope

- Portable Inverted Tissue Culture Microscoe RTC-1P

- Digital Research Microscope RXLr-4NX

- Digital Spinneret Inspection Microscope RIS-45

- Stereo Microscope RSM-4

- Inverted Metallurgical Microscope RMM-77

- Toolmaker Microscope Large RTM-900DR

- Trinocular Projection Microscope PRM-18T

- Advanced Research Microscope RXLr-5NXM2

- Portable Grooved Metallurgical Microscope RMM-6L

- Student Compound Microscope RM-2A

- Trinocular Inverted Tissue Culture Microscope RTC-8A

- Binocular Research Microscope RXL-5B

- BINOCULAR STEREO ZOOM MICROSCOPE RSM-8AS

- Portable Metallurgical Microscope RMM-5A

- Biological LCD Microscope RXL-4LCD

- Student Projection Microscope PRM-11A

- Tool Maker's Microscope RTM-500

- Sieves Digital Microscope RSP-90

- Confocal Microscope RTC-7 CON

- Motorized Comparision RCM-18

- Senior Inspection Spinneretscope RIS-30

- Toolmaker's Microscope RTM-900DL

- Penta Head Microscope/ Multi View Head Microscope RXLr-5000

- Upright Binocular Research Microscope RXLr-5Nx

- PCB Inspection Video Stereoscope Microscope RPCB-45

- Deca Head Microscope RXLr-5 Nx

- SPINNERET MICROSCOPE RIS-90

- Dissecting Microscope RDM-2

- Trinocular Upright Metallurgical Microscope RXM-7T

- Senior Dissecting Microscope RDM-4

- Inverted Fluorescence Microscope RTC-7A

- Trinocular Polarizing Microscope RPL-55T

- Student School Microscope RM-2

- Metallurgical Microscope RMM-88

- CONFOCAL MICROSCOPES RTC-7 CON

- Advance Stereo Zoom Microscope RSMr-10

- Stereo Inspection Scope

- Trinocular Stereo Zoom Microscope RSM-9

- Biological Research Microscope RXLr-5 Series

- Stereo Inspection Microscope RSMr-X8

- Polarizing Projection Microscope RPL-4

- Projection Microscope PRM-12/12A

- Trinocular Coaxial Microscope RXL-4T

- Gemological Microscope RGM-8

- Digital Biological Microscope RXLr-4D

- Student Medical Microscope RM-3

- Inverted Tissue Culture Microscope RTC-6

- Laboratory Microscope RM-600B

- Advanced Research Material Microscope RXLr-5M

- Coaxial Microscope RXL-4

- Tissue Culture Microscope RTC-5

- Advanced Inverted Phase Microscope RTC-7NX

- Measuring Microscope ROM-100D

- Microtomes

- Knife Sharpener Microtome RSM-100

- Rocking Microtome RMT-10

- Sliding Microtome RMT-45

- Rotary Microtome RMT-20A

- Advance Rotary Microtome RMT-30A

- Slide Staining Machine RSSD-23

- Freezing Microtome RMT-40

- Senior Precision Rotary Microtome RMT-30

- Fully Automatic Rotary Microtome RMT-75

- Hand Table Microtome RMT-5

- Manual Rotary Microtome RMT-25

- Rotary Microtome RMT-20 (Erma Type)

- Precision Fiber Microtome RMT-55

- CRYOSTAT MICROTOME RSC-28

- Optical Instruments

- Digital Vertical Autoclave RAV-50

- Optical Charpy Projector RPP-250C

- Profile Projector RPP-3000DP

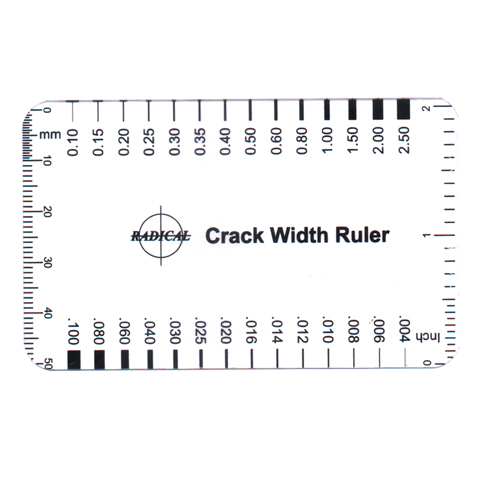

- Crack Width Ruler RWR-7

- Universal Profile Projector RPP-3000

- Automatic Metallographic Polishing Machine RSMP-2S

- Illuminated Flexible Arm Magnifier RBM-104

- Gem Illuminated Spectroscope RDV-77

- ILLUMINATED OPTICAL COMPARATOR RBM-103

- Shop Microscope (Measuring Microscope) ROM Series

- Brinell Microscope RBM-55

- Grooved Laboratory Microscope RMM-6L

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Bone and Brain Cutting Machine RBCM-55

- Embalming Machine RSTI-130

- High Temperature Oven RSTI-108

- SEMI AUTOMATIC ROTARY MICROTOME RMT-35

- SLIDING MICROTOME RMT-45

- Tissue Flotation Water Bath RSTI-138

- Laboratory Incubator RSTI-108

- Hot Air Oven Digital RSTI-102

- DIGITAL LABORATORY INCUBATOR RSTI-Series

- Laminar Air Flow Horizontal

- Industrial Hot Air Oven RSTI-104

- Slide Cabinet RS-105 Series

- Vertical Autoclave

- Flocculator Jar Test Apparatus RS-1924

- Lab Instrument

- Precision Water Bath RSTI-137

- Revolutionary General Purpose Digital Centrifuge RST-8M

- Digital Magnetic Stirrer RSTI-156

- Laboratory Rectangular Hot Plates RSTI-146

- pH or mv or Conductivity

- VDRL ROTATOR (VARIABLE SPEED) RSTI-150

- Vortex Shaker RSTI-151

- Round Centrifuge RSC-15

- Digital Photo Colorimeter RSPC-9

- Incubator Shaker Water Bath RSTI-140

- Serological Water Bath RSTI-134

- Haematocrit Centrifuge RST-15

- Disintegration Test Apparatus RS-901

- Dual Channel Flame Photometer RS-391

- BOD INCUBATOR RSTI-110

- Digital Turbidity Meter RS-335

- Water Distillation with Metal Heater RSLWS-MH-40M

- Heating Mantle RSTI-148

- Tablet Dissolution Test Apparatus (6 Basket) RS-1916

- Haemoglobin Meter RSHB-50

- MAGNETIC STIRRER with HOT PLATE RSTI-156

- Double Disc Polishing Machine Semi Automatic RSMP-2S+MPT

- Rectangular Water Bath RSTI-135

- Hemoglobin Meter (Sahli's) RSHB-10

- PASS BOX DYNAMIC

- GROSSING TABLE

- Micro Centrifuge 16000 R.P.M. RST-16

- Dissolved Oxygen Meter RS-801

- Hand Specimen Leveler Press MM-18

- COOLING PLATE

- MICROPROCESSOR PH METER RS-1013

- DIGITAL FLAME PHOTOMETER RS-1381

- pH/mV/TEMPERATURE TESTER RS-7011

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER RS-101

- Auto Karl Fischer Titrimeter RT-761

- Atomic Model Set (Euro Design)

- Laboratory DEEP Freezer RSTI-121

- Blood Bank Refrigerator RSTI-126

- Heating Mantles RSTI-148

- Laboratory Round Hot Plate RSTI-145

- Melting Point Apparatus RS-934

- Jominy End Quench Apparatus RJQA-45

- Stereo Zoom Microscope

- Jewellery Making Microscope RGM-10

- Binocular Stereo Microscope RSM-5

- Motorized Stereo Microscope RSMr-X8

- Articulated Trinocular Stereo Zoom Microscope RSM-9AS

- Universal Stereo Zoom Microscope RSM-8U

- Stereo Microscope RSM-4T

- Binocular Stereo Microscope RSM-4F

- Advance Stereo Zoom Microscope RSMr-3T

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Stereo Inspection Microscope RSM-15

- Digital 3D Inspection Microscope RSZ-3D

- Polarising Microscopes

- Lab Consumables

- Desiccator (Vaccum)

- Slide Mailer

- Carboy with Wide Handle

- Scoop PP

- ORBITAL SHAKING INCUBATOR RSTI-111

- Atomic Model Set (PP)

- Carboy with Stopcock

- Atomic Model Set

- DIGITAL LABORATORY RECTANGULAR HOT PLATES RSTI-146

- Desiccator (plain)

- Dropping Bottles

- Wash Bottles

- Coplin Jar Polypropylene

- Slide Box

- Slide Tray

- Slide Draining Tray

- PCR Tube Rack with Hinges - Autoclavable

- MCT Box

- Rotatable Multi Rack

- Measuring Cylinder Hexagonal

- Draining Lab Rack

- Profile Projector

- Vertical Profile Projector RPP-60DR+

- High Sharpness Profile Projector RPP-350 DR

- Profile Projector RPP-150

- Bench Type Profile Projector RPP-500HDR

- Profile Projector RPP-500

- Profile Projector

- Charpy Profile Projector RPP-250C

- Coaxial Profile Projector RPP-3000

- Profile Projector RPP-350

- Profile Projector Shadowgraph RPP-3000DP

- Profile Projector (Floor Model) RPP-60DR

- PROFILE PROJECTOR

- Anotomy Model

- Metallurgical Microscope

- INVERTED METALLURGICAL MICROSCOPE RMM-88S

- Research Material Microscope

- Advanced Laboratory Metallurgical Microscope RXLr-4M

- Emery Paper (Velvet)/Sand Paper

- Belt Grinder/Polisher RBP-100

- Single Disc Polishing Machine RPM-22S

- Double Disc Digital Polishing Machine RPM-33D

- ABRASIVE CUT-OFF MACHINE RACM-55

- Metallographic Specimen Mounting Press RHM-2B-30

- Metallographic Hot Mounting Machine RHM-5

- Digital Hot Mounting Machine RHM-2

- Portable Metallurgical Microscope RMM-5L

- Lab items

- Microscope

- Contact Us

Brinell Microscope RBM-55

7200.0 INR/Piece

Product Details:

- Lens High-resolution plano-convex lens

- Measurement Corneal curvature, height, power map

- Theory Placido disk-based reflection method

- Objective Non-contact corneal surface analysis

- Product Type Brinell Microscope

- Material MS

- Size Standard

- Click to view more

X

Brinell Microscope RBM-55 Price And Quantity

- 7200.0 INR/Piece

- 1 Piece

Brinell Microscope RBM-55 Product Specifications

- Placido disk-based reflection method

- Standard

- Corneal curvature, height, power map

- Brinell Microscope

- Non-contact corneal surface analysis

- High-resolution plano-convex lens

- MS

Product Description

Brinell Microscope RBM-55

Evaluation of the spherical indentations formed by the Brinell hardness test requires a microscope with a measuring length of 6mm. and least count graduations of 0.01 mm. The Brinell hardness measuring microscope from RADICAL offers precisely these features.

Our Brinell Microscope RBM-55 is a compact, yet durable instrument, making it suitable for linear measurement in the field and laboratory. This instrument makes accurate measurements of the indentations for all Brinell type hardness testers.

This microscope is designed to measure easily the Brinell hardness value of different ferrous and non-ferrous metals including crude or annealed steel, non austenitic steel only, quenched and tempered steel,

non austenitic steel only, cast iron, brass casting, rolled brass, rolled cooper, alloy of tin and bronze and casting of aluminum alloy.

It can determine the Brinell hardness by measuring the diameters of the indentations left on the test piece and the standard hardness test block. The indentations are obtained by the steel ball of the tester located between the piece and test block. The Brinell value can be obtained by referring the Conversion Table after measuring the indentations by the readout microscope. These are widely used in shop, material supplier, plant and quality control due to lightweight, easy operation and convenience.

Specimen/Graticule can be sharp focus by rotation the Microscope Eyepiece. The microscope tube can be rotated upto 40 to align the specimen with the scale. Graduated micrometer drum is having graduations

0 to 50, each Division/Least Count = 0.01mm.

The stage micrometer can be used to check and insure that the Brinell Microscope is correctly calibrated.

Technical Specifications :

Magnification : 20x

Reticle scale length : 7.00mm.

Least Count : 0.01mm.

Field of View : 6.00mm.

Weight : 1.500 Kg.

Illumination : Cordless LED &

220 Volt Tungsten

Advanced Placido Disk Reflection Theory

The RBM-55 microscope utilizes Placido disk-based reflection to analyze corneal topography non-invasively. This method reflects concentric rings onto the corneal surface, capturing detailed curvature data and power maps for comprehensive ocular assessment.

High-Resolution Optics for Accurate Measurements

With a precision plano-convex lens crafted from MS material, this microscope achieves high-quality imaging and accurate measurement of corneal features. The non-contact approach minimizes patient discomfort and reduces contamination risk during the examination.

FAQ's of Brinell Microscope RBM-55:

Q: How does the Brinell Microscope RBM-55 measure corneal curvature?

A: The RBM-55 employs the Placido disk reflection method, projecting concentric rings onto the corneal surface and capturing reflected patterns. This data allows precise assessment of corneal curvature, height, and power map without any physical contact.Q: What are the main benefits of using a non-contact corneal surface analysis microscope?

A: Non-contact analysis, as offered by the RBM-55, eliminates potential infection risks and physical discomfort, ensuring safer and more hygienic procedures for both patients and clinicians.Q: When is the Brinell Microscope RBM-55 most commonly used in ophthalmology?

A: This microscope is typically used during preoperative assessments for refractive surgery, routine eye exams, and monitoring corneal health, offering valuable insights into corneal structure and abnormalities.Q: Where can I purchase the Brinell Microscope RBM-55 in India?

A: You can acquire the RBM-55 through authorized distributors, exporters, manufacturers, suppliers, and wholesalers across India. Contact local medical equipment vendors for specific availability.Q: What is the practical application process of the RBM-55 microscope?

A: To use the RBM-55, position the patient so the microscope's lens aligns with the eye, activate the device, and allow it to project the Placido disk rings onto the cornea. The reflected image is then analyzed to generate corneal curvature and power maps.Q: How does the high-resolution plano-convex lens enhance the accuracy of measurements?

A: The specialized plano-convex lens made from MS material provides sharp, detailed imaging, which enhances the reliability of corneal measurement for diagnostic and research purposes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free