- Home Page

- Company Profile

-

Our Products

- Microscope

- Portable Inverted Tissue Culture Microscoe RTC-1P

- Digital Research Microscope RXLr-4NX

- Digital Spinneret Inspection Microscope RIS-45

- Stereo Microscope RSM-4

- Inverted Metallurgical Microscope RMM-77

- Toolmaker Microscope Large RTM-900DR

- Trinocular Projection Microscope PRM-18T

- Advanced Research Microscope RXLr-5NXM2

- Portable Grooved Metallurgical Microscope RMM-6L

- Student Compound Microscope RM-2A

- Trinocular Inverted Tissue Culture Microscope RTC-8A

- Binocular Research Microscope RXL-5B

- BINOCULAR STEREO ZOOM MICROSCOPE RSM-8AS

- Portable Metallurgical Microscope RMM-5A

- Biological LCD Microscope RXL-4LCD

- Student Projection Microscope PRM-11A

- Tool Maker's Microscope RTM-500

- Sieves Digital Microscope RSP-90

- Confocal Microscope RTC-7 CON

- Motorized Comparision RCM-18

- Senior Inspection Spinneretscope RIS-30

- Toolmaker's Microscope RTM-900DL

- Penta Head Microscope/ Multi View Head Microscope RXLr-5000

- Upright Binocular Research Microscope RXLr-5Nx

- PCB Inspection Video Stereoscope Microscope RPCB-45

- Deca Head Microscope RXLr-5 Nx

- SPINNERET MICROSCOPE RIS-90

- Dissecting Microscope RDM-2

- Trinocular Upright Metallurgical Microscope RXM-7T

- Senior Dissecting Microscope RDM-4

- Inverted Fluorescence Microscope RTC-7A

- Trinocular Polarizing Microscope RPL-55T

- Student School Microscope RM-2

- Metallurgical Microscope RMM-88

- CONFOCAL MICROSCOPES RTC-7 CON

- Advance Stereo Zoom Microscope RSMr-10

- Stereo Inspection Scope

- Trinocular Stereo Zoom Microscope RSM-9

- Biological Research Microscope RXLr-5 Series

- Stereo Inspection Microscope RSMr-X8

- Polarizing Projection Microscope RPL-4

- Projection Microscope PRM-12/12A

- Trinocular Coaxial Microscope RXL-4T

- Gemological Microscope RGM-8

- Digital Biological Microscope RXLr-4D

- Student Medical Microscope RM-3

- Inverted Tissue Culture Microscope RTC-6

- Laboratory Microscope RM-600B

- Advanced Research Material Microscope RXLr-5M

- Coaxial Microscope RXL-4

- Tissue Culture Microscope RTC-5

- Advanced Inverted Phase Microscope RTC-7NX

- Measuring Microscope ROM-100D

- Microtomes

- Knife Sharpener Microtome RSM-100

- Rocking Microtome RMT-10

- Sliding Microtome RMT-45

- Rotary Microtome RMT-20A

- Advance Rotary Microtome RMT-30A

- Slide Staining Machine RSSD-23

- Freezing Microtome RMT-40

- Senior Precision Rotary Microtome RMT-30

- Fully Automatic Rotary Microtome RMT-75

- Hand Table Microtome RMT-5

- Manual Rotary Microtome RMT-25

- Rotary Microtome RMT-20 (Erma Type)

- Precision Fiber Microtome RMT-55

- CRYOSTAT MICROTOME RSC-28

- Optical Instruments

- Digital Vertical Autoclave RAV-50

- Optical Charpy Projector RPP-250C

- Profile Projector RPP-3000DP

- Crack Width Ruler RWR-7

- Universal Profile Projector RPP-3000

- Automatic Metallographic Polishing Machine RSMP-2S

- Illuminated Flexible Arm Magnifier RBM-104

- Gem Illuminated Spectroscope RDV-77

- ILLUMINATED OPTICAL COMPARATOR RBM-103

- Shop Microscope (Measuring Microscope) ROM Series

- Brinell Microscope RBM-55

- Grooved Laboratory Microscope RMM-6L

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Bone and Brain Cutting Machine RBCM-55

- Embalming Machine RSTI-130

- High Temperature Oven RSTI-108

- SEMI AUTOMATIC ROTARY MICROTOME RMT-35

- SLIDING MICROTOME RMT-45

- Tissue Flotation Water Bath RSTI-138

- Laboratory Incubator RSTI-108

- Hot Air Oven Digital RSTI-102

- DIGITAL LABORATORY INCUBATOR RSTI-Series

- Laminar Air Flow Horizontal

- Industrial Hot Air Oven RSTI-104

- Slide Cabinet RS-105 Series

- Vertical Autoclave

- Flocculator Jar Test Apparatus RS-1924

- Lab Instrument

- Precision Water Bath RSTI-137

- Revolutionary General Purpose Digital Centrifuge RST-8M

- MAGNETIC STIRRER with HOT PLATE RSTI-156

- Laboratory Rectangular Hot Plates RSTI-146

- pH or mv or Conductivity

- VDRL ROTATOR (VARIABLE SPEED) RSTI-150

- Vortex Shaker RSTI-151

- Round Centrifuge RSC-15

- Digital Photo Colorimeter RSPC-9

- Incubator Shaker Water Bath RSTI-140

- Serological Water Bath RSTI-134

- Haematocrit Centrifuge RST-15

- Disintegration Test Apparatus RS-901

- Dual Channel Flame Photometer RS-391

- BOD INCUBATOR RSTI-110

- Digital Turbidity Meter RS-335

- Water Distillation with Metal Heater RSLWS-MH-40M

- Heating Mantle RSTI-148

- Tablet Dissolution Test Apparatus (6 Basket) RS-1916

- Haemoglobin Meter RSHB-50

- Double Disc Polishing Machine Semi Automatic RSMP-2S+MPT

- Rectangular Water Bath RSTI-135

- Hemoglobin Meter (Sahli's) RSHB-10

- PASS BOX DYNAMIC

- GROSSING TABLE

- Micro Centrifuge 16000 R.P.M. RST-16

- Dissolved Oxygen Meter RS-801

- Digital Magnetic Stirrer RSTI-156

- Hand Specimen Leveler Press MM-18

- COOLING PLATE

- MICROPROCESSOR PH METER RS-1013

- DIGITAL FLAME PHOTOMETER RS-1381

- pH/mV/TEMPERATURE TESTER RS-7011

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER RS-101

- Auto Karl Fischer Titrimeter RT-761

- Atomic Model Set (Euro Design)

- Laboratory DEEP Freezer RSTI-121

- Blood Bank Refrigerator RSTI-126

- Heating Mantles RSTI-148

- Laboratory Round Hot Plate RSTI-145

- Melting Point Apparatus RS-934

- Jominy End Quench Apparatus RJQA-45

- Stereo Zoom Microscope

- Jewellery Making Microscope RGM-10

- Binocular Stereo Microscope RSM-5

- Motorized Stereo Microscope RSMr-X8

- Articulated Trinocular Stereo Zoom Microscope RSM-9AS

- Universal Stereo Zoom Microscope RSM-8U

- Stereo Microscope RSM-4T

- Binocular Stereo Microscope RSM-4F

- Advance Stereo Zoom Microscope RSMr-3T

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Stereo Inspection Microscope RSM-15

- Digital 3D Inspection Microscope RSZ-3D

- Polarising Microscopes

- Lab Consumables

- Desiccator (Vaccum)

- Slide Mailer

- Carboy with Wide Handle

- Scoop PP

- ORBITAL SHAKING INCUBATOR RSTI-111

- Atomic Model Set (PP)

- Carboy with Stopcock

- Atomic Model Set

- DIGITAL LABORATORY RECTANGULAR HOT PLATES RSTI-146

- Desiccator (plain)

- Dropping Bottles

- Wash Bottles

- Coplin Jar Polypropylene

- Slide Box

- Slide Tray

- Slide Draining Tray

- PCR Tube Rack with Hinges - Autoclavable

- MCT Box

- Rotatable Multi Rack

- Measuring Cylinder Hexagonal

- Draining Lab Rack

- Profile Projector

- Vertical Profile Projector RPP-60DR+

- High Sharpness Profile Projector RPP-350 DR

- Profile Projector RPP-150

- Bench Type Profile Projector RPP-500HDR

- Profile Projector RPP-500

- Profile Projector

- Charpy Profile Projector RPP-250C

- Coaxial Profile Projector RPP-3000

- Profile Projector RPP-350

- Profile Projector Shadowgraph RPP-3000DP

- Profile Projector (Floor Model) RPP-60DR

- PROFILE PROJECTOR

- Anotomy Model

- Metallurgical Microscope

- INVERTED METALLURGICAL MICROSCOPE RMM-88S

- Research Material Microscope

- Advanced Laboratory Metallurgical Microscope RXLr-4M

- Emery Paper (Velvet)/Sand Paper

- Belt Grinder/Polisher RBP-100

- Single Disc Polishing Machine RPM-22S

- Double Disc Digital Polishing Machine RPM-33D

- ABRASIVE CUT-OFF MACHINE RACM-55

- Metallographic Specimen Mounting Press RHM-2B-30

- Metallographic Hot Mounting Machine RHM-5

- Digital Hot Mounting Machine RHM-2

- Portable Metallurgical Microscope RMM-5L

- Lab items

- Microscope

- Contact Us

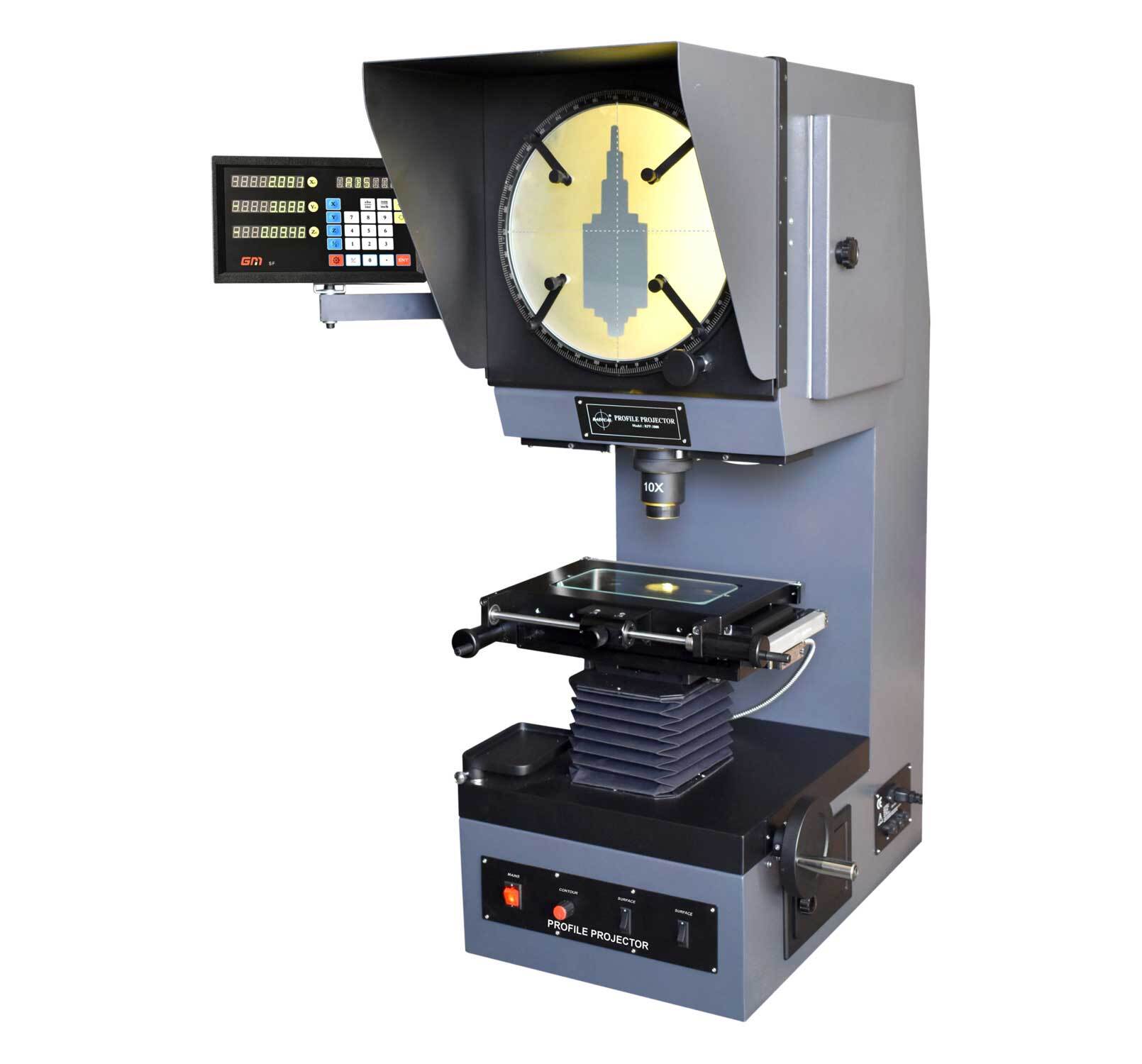

High Sharpness Profile Projector RPP-350 DR

380000.0 INR/Piece

Product Details:

- Use Other

- Portable No

- Brightness Adjustable ISO

- Resolution 0.001mm/ 0.00005"

- Projection Distance NA Millimeter (mm)

- Lamp LED/Halogen

- Lens 10x Objective (Standard)

- Click to view more

X

High Sharpness Profile Projector RPP-350 DR Price And Quantity

- 380000.0 INR/Piece

- 1 Piece

High Sharpness Profile Projector RPP-350 DR Product Specifications

- 0.001mm/ 0.00005"

- Adjustable ISO

- 10x Objective (Standard)

- 150 Watt (w)

- Other

- Profile Projector

- LED/Halogen

- NA Millimeter (mm)

- No

- 24 Volt (v)

- NA

- NA

High Sharpness Profile Projector RPP-350 DR Trade Information

- NA

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- 2 Piece Per Month

- 2 Week

- Exports Worthy Cartons

- Western Europe, Eastern Europe, Central America, Africa, Middle East, South America, Australia, Asia, North America

- All India

- Certificates ISO 9001, ISO 9022-1, ISO 13485, ISO 140001, CE

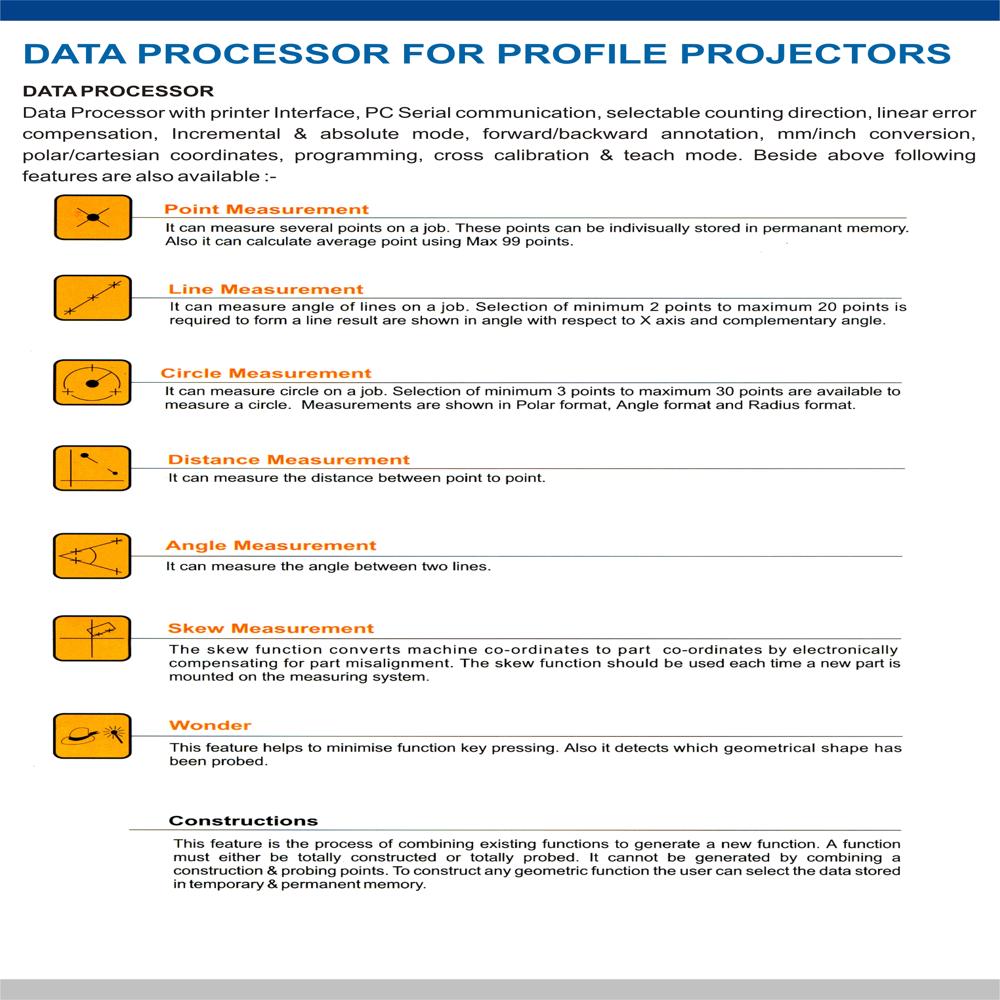

Product Description

ScreenAntiglare hard glass screen, graduated & rotatable through 360 deg having least count 1 minute of an arc.MirrorsOptically true with surface hard coated to ensure optimum light reflection for best image contrast, long life and edge to edge sharpness on the projection screen.

Contour Illumination is provided with a 24V 150W halogen lamp having a built in condenser system.

EPI-IlluminationA Specially designed LED or 12V 100W halogen light ensures uniform surface illumination system for the above.

ElectricalMains input 220-240 volts AC having built in transformers, On-Off Switch, variable intensity controller for both illumination system, indicator and glass fuse.

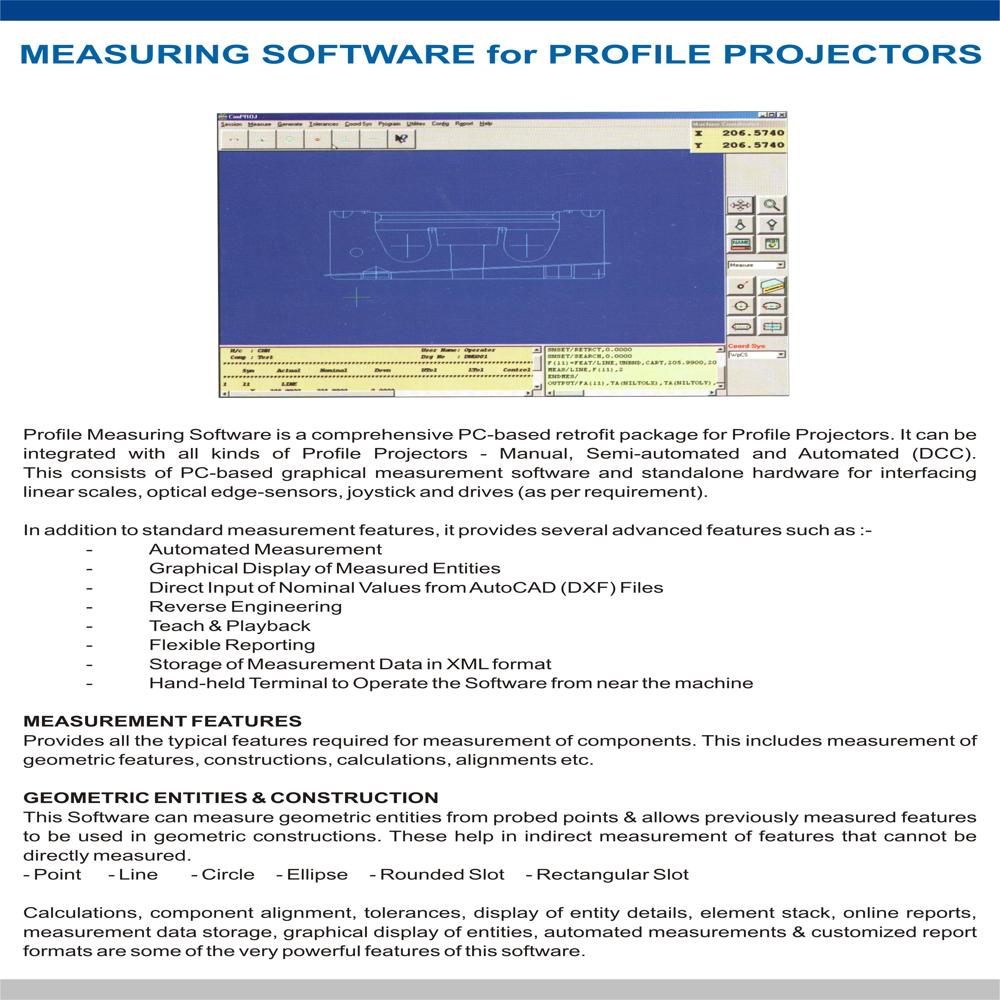

High Precision Measurement Tool

Engineered for accuracy, the RPP-350 DR profile projector boasts a fine resolution and standard 10x lens, making it ideal for inspecting small components with complex geometries. It ensures precise dimensional analysis for a variety of applications.

Versatile Lighting Options

With a powerful 150 Watt LED/Halogen lamp and customizable ISO brightness, this projector adapts easily to diverse sample materials and surface finishes, maximizing visibility and measurement clarity during operation.

Reliable and User-Friendly Design

Built for stationary use, the RPP-350 DR is sturdy and simple to operate, perfect for industrial settings where regular, detailed inspection is necessary. Its robust construction guarantees longevity and consistent performance.

FAQ's of High Sharpness Profile Projector RPP-350 DR:

Q: How is the RPP-350 DR Profile Projector typically used in industrial environments?

A: The RPP-350 DR is primarily used for non-contact inspection and measurement of small mechanical parts, profiles, and components. Its high-resolution optics allow users to precisely assess dimensions and detect any manufacturing defects without physically touching the part.Q: What process should be followed to achieve accurate measurements with this profile projector?

A: For best accuracy, place the component on the projector stage, adjust the focus using the 10x objective lens, and modify the brightness as needed via the adjustable ISO. Align the part's edge with the measurement grid or reticle displayed, and use the fine resolution to take readings.Q: When is it beneficial to choose the RPP-350 DR over other inspection instruments?

A: This projector is most beneficial when high measurement accuracy and detailed observation are required, particularly for small or intricate components. It is suitable for applications in tool rooms, manufacturing units, and laboratories demanding precise dimensional inspection.Q: Where can I purchase the RPP-350 DR Profile Projector?

A: The RPP-350 DR is available from various distributors, exporters, manufacturers, suppliers, and wholesalers throughout India. You can inquire with authorized dealers or contact the manufacturer directly for availability and purchase options.Q: What are the advantages of using a 10x objective lens in this projector?

A: The standard 10x objective lens offers enhanced magnification and detail, making it easier to inspect fine features and measure small parts accurately, which is critical for quality control and research applications.Q: How does the adjustable brightness contribute to the user's experience?

A: Adjustable brightness, controlled via ISO settings, allows users to tailor the illumination to suit different part surfaces and materials, ensuring optimal contrast and clear visual representation for precise measurement every time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free